Hopper feeders are designed to be loaded directly from wheel loaders, grab cranes or excavators. This means that the same piece of equipment can be used to

Hopper Feeders are designed to hold a buffer of material within the hopper ensuring a regulated flow of material to travel onto the main incline conveyor. Hopper Feeders can either be track or wheel mounted providing excellent mobility – adapted to suit your environment!

And when the project is complete – the Telestack Hopper Feeder commands an excellent resale value highly! Win Win!

The Telestack Hopper Feeder range can receive a payload from a wheel loader small utility loader/excavator right up to a CAT 994 – and everything in between! For anyone that doesn’t appreciate the size of this beast, check this out:

HF 10T Mobile Hopper Feeder

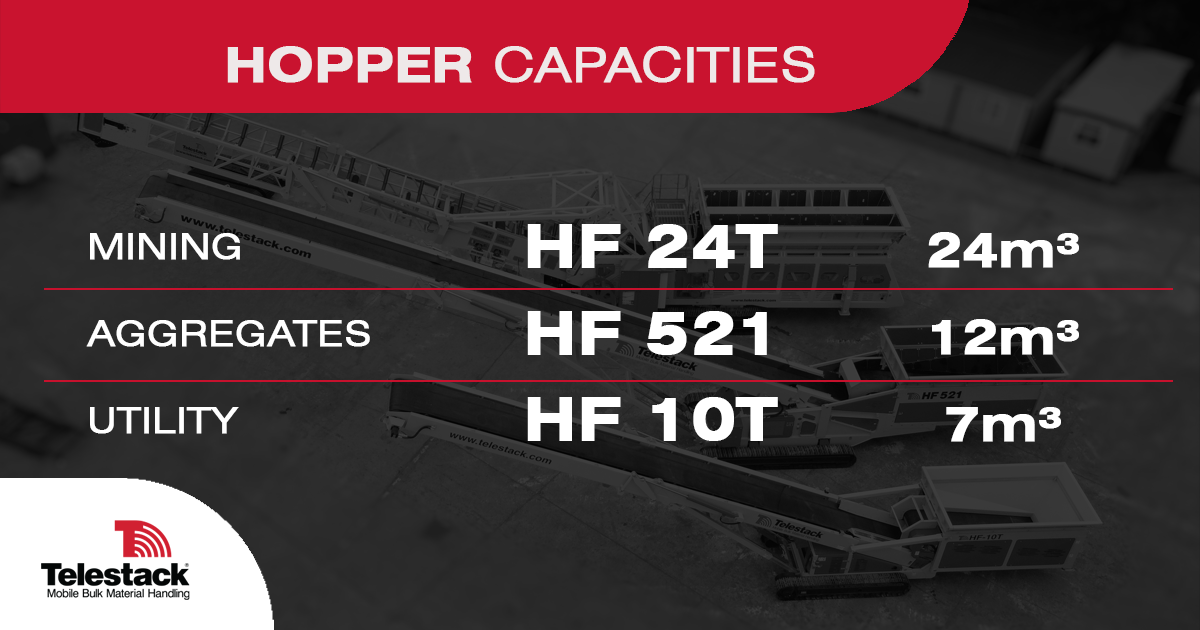

The utility entry level HF 10T track mounted conveyor gives unrivalled mobility and flexibility on site. It is designed to work at production rates of up to 300tph (350 Ton per hr) can handle a wide range of dry bulk materials.

When in working position @ 18° it has a conical stockpile height of 5.24m (17 ft. 1”) and a stockpile capacity (mass) of 424 tonnes (468 ton). The standard hopper configuration comes with 300mm (12”) hopper extensions achieving a hopper capacity of 6.8 m³ (8.9yds³).

HF 10T Key Features

__________________________________________________________________________________________

HF 521 Mobile Hopper Feeder

HF 521 is a track mounted fully mobile conveyor designed to work at production rates of up to 500tph (550 Ton per hr) with a maximum lump size of up to 150mm (6”). When in working position @22o it has a conical stockpile height of 8.55m (27 ft. 10”) and a stockpile capacity (mass) of 1844 tonnes (2033 ton).When being used to feed auxiliary equipment, with the 700mm (28”) tapered hopper extension it allows a 11.85m³ (15.5yds³) heaped capacity.

HF 521 – Key Features

_________________________________________________________________________________________

HF 24 T Mobile Hopper Feeder

The HF 24T is a heavy duty fully mobile conveyor designed to work at production rates up to 3,000tph in a mine or port. It has a large 24m³ (32yds³) hopper capacity to suit all types of applications and production rates with optional boom extensions for various discharge heights. Its hopper is designed to offer integral strength and stability in working position as standard and has an engine protection shutdown system. With a maximum lump feed size of up to 150mm (5”), the HF 24T has the ability to be fed easily by a CAT 992/994 or similar.

HF 24T- Key Advantages

__________________________________________________________________________________________